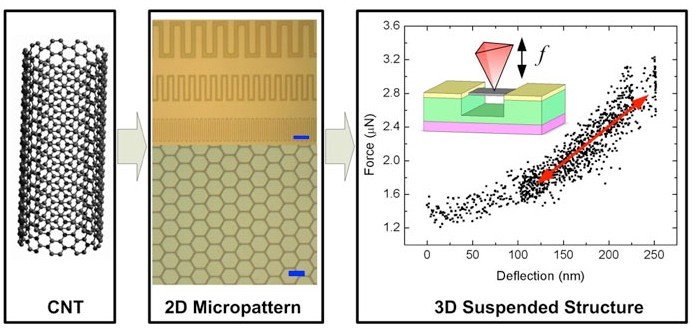

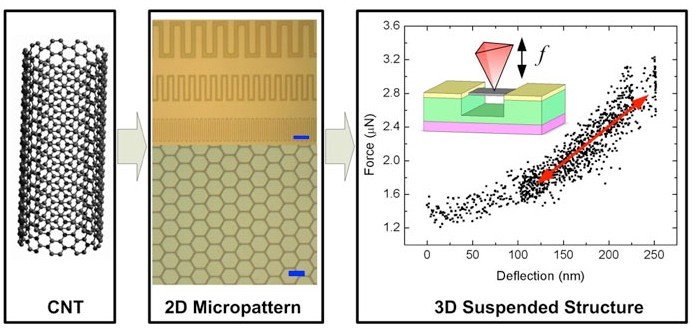

Engineers in the US have fabricated 2D micropatterns and 3D suspended thin-film structures using carbon nanotubes as a building block via lithography-compatible layer-by-layer nano self-assembly. They used well established IC fabrication techniques along with the "bottom-up" construction of nanotubes and applied a further process to manufacture the suspended micro-beam, which is a basic structure for actuators in micro/nanoscale systems.

The group, led by Tianhong Cui at the University of Minnesota, US, has explored the fundamental issues of fabrication by characterizing the devices step by step. As a result, the scientists observed reduced electrical resistance of the stripe film pattern when thin-film was released. More importantly, the flexural Young's modulus they found using a nanoindentation technique was on the order of 500–800 GPa. The stiff CNT thin-film micropatterns and suspended beam architecture have a variety of potential applications including novel physical sensors, nanoelectromechanical switches and other M/NEMS devices.

The team is using the bridge-like structures for nanoswitch applications thanks to the electrical

Source: nanotechweb.org