Orders-of-magnitude effective elastic modulus reductions in aligned carbon nanotubes (CNTs) and their architectures originate from their local curvature, commonly known as waviness. Pre-established theoretical frameworks are unable to adequately describe the three-dimensional morphology of CNTs, which leads to large over-predictions of their elastic response. Reporting in Nanotechnology, researchers at the Massachusetts Institute of Technology use a newly developed simulation framework capable of modeling > 105 CNTs with stochastic three-dimensional morphologies to quantify the impact of CNT waviness on the deformation modes that govern the stiffness of their polymer matrix nanocomposites.

While early reports of the high elastic modulus and low density of carbon nanotubes (CNTs) encourages their use in large-scale commercial composite structures, CNT composites manufactured on the centimetre to metre length-scales behave very differently from what early theoretical models originally predicted. This difference in behaviour is caused by CNT structural and morphological non-idealities, which are inevitable results of their synthesis process via highly scalable chemical vapour deposition techniques, but were not considered in the original theoretical studies. More recent work indicates that the local curvature of the CNTs, which is normally quantified using a non-dimensional waviness ratio that assumes a simple sinusoidal or helical functional form of the waviness, is a major factor contributing to the order of magnitude stiffness over-predictions of early models. However, due to the oversimplified descriptions of the CNT morphology used by these previous studies, little is known about the mechanics of wavy CNTs with realistic stochastic 3D morphology undergoing deformation, and how the complicated CNT morphology will evolve as a function of CNT packing proximity to lead to the observed stiffness enhancements in aligned CNT polymer matrix nanocomposites (A-PNCs).

CNTs with realistic morphology

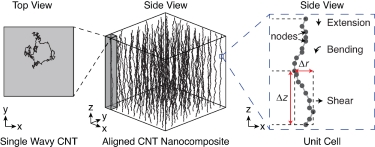

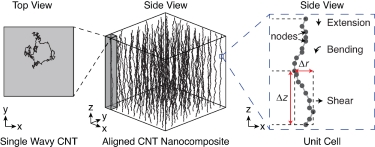

CNTs with stochastic 3D morphologies are assembled as arrays of nodes in xyz space. The CNT waviness is applied using node displacements in the x and y directions via Gaussian distributions (see Figure 1), and is quantified by their tortuosity, a stochastic parameter that is evaluated using the arc length of each CNT. This CNT arc length is matched to the experimentally evaluated CNT waviness ratio, an analytical parameter, using the arc length of a sine wave. Arrays comprised of > 105 stochastic wavy CNTs are assembled in a layer-by-layer fashion, where each layer is comprised of the square root of the total number of CNTs in the simulation. This technique could enable CNT structures to be studied at true scale, where a CNT simulation comprised of > 106 stochastic wavy CNTs could have an area of 0.1 mm x 0.1 mm.

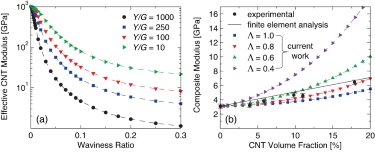

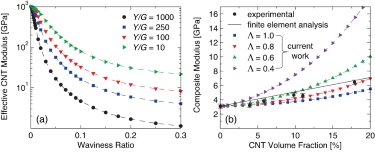

Using their intrinsic longitudinal (Y) and shear (G) moduli, the effective stiffness of the CNTs that reinforce the A-PNCs is evaluated (see Figure 2(a)). As Figure 2(a) illustrates, the effective reinforcement modulus of CNTs is diminished as their waviness increases, but this effect is not as pronounced when the ratio of Y/G is small. Using the effective stiffness of the CNTs, the elastic response of the A-PNCs in the longitudinal direction is also quantified and compared to experimental results and previous predictions by a finite element method assuming a constant waviness ratio (see Figure 2 (b)). Figure 2(b) shows that by more accurately describing the waviness of the CNTs and their evolution with the CNT volume fraction, which is controlled using Λ, the current method is able to explain the observed enhancements in the A-PNC modulus as a function of the CNT volume fraction. This implies that using representative descriptions of the CNT morphology, more accurate material property turning and prediction may become possible.

Using their intrinsic longitudinal (Y) and shear (G) moduli, the effective stiffness of the CNTs that reinforce the A-PNCs is evaluated (see Figure 2(a)). As Figure 2(a) illustrates, the effective reinforcement modulus of CNTs is diminished as their waviness increases, but this effect is not as pronounced when the ratio of Y/G is small. Using the effective stiffness of the CNTs, the elastic response of the A-PNCs in the longitudinal direction is also quantified and compared to experimental results and previous predictions by a finite element method assuming a constant waviness ratio (see Figure 2 (b)). Figure 2(b) shows that by more accurately describing the waviness of the CNTs and their evolution with the CNT volume fraction, which is controlled using Λ, the current method is able to explain the observed enhancements in the A-PNC modulus as a function of the CNT volume fraction. This implies that using representative descriptions of the CNT morphology, more accurate material property turning and prediction may become possible.

More information about this research can be found in the journal Nanotechnology 27 035701.