Researchers at Rice University in the US have measured the stiffness of different types of joined-up nanotubes in the most detail ever, and have found that some shapes are tougher than others. The work could help in the design of nanotube-based materials for specific applications in the future, as well as to build 3D structures from these nanomaterials.

When carbon nanotubes are grown in a furnace, different shapes, such as curved, kinked or branched, are formed and these tubes join up in different configurations. A team led byPulickel Ajayan and Boris Yakobson studied five different shapes of joined-up tubes. These were: straight nanotubes (that the researchers named “I”), branched nanotubes (which they called “Y”), covalently joined tubes that cross each other (“X”), nanotubes that join at any angle (“Λ”) and, finally, non-covalent tubes that bind through van der Waals or other weak forces (“Ω”).

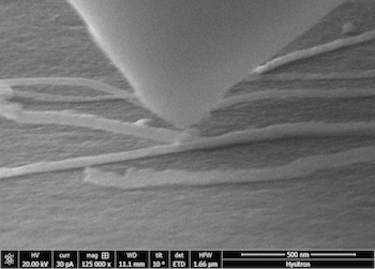

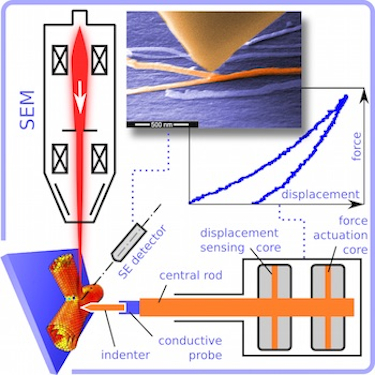

Team member Chandra Sekhar Tiwary in Ajayans Lab applied pressure to the junctions between the differently shaped joined-up nanotubes using a picoindenter installed on a scanning electron microscope at Hysitron in Minneapolis. The indenter measures force in nanonewtons and displacement in nanometres. The nanotubes were prepared by Rice researcher Sehmus Ozden, who dispersed them in solution and dried them on a silicon substrate before placing them in the microscope.

A picoindenter approaches the junction of a branched nanotube

The researchers made sure they were looking at nanotubes that were actually joined together and not just ones that were simply very close to each other but not joined. This was no easy task, they say, since the space between two nanotubes can be as small as just 1 nm, while the resolution of the microscope is 5 nm. The team overcame this problem by picking up one side of a tube to make sure it was welded to another tube. If a tube came away from another tube easily, it was ignored in the experiment.

The researchers found that the Xs were the stiffest type of joined-up tube and the ones that bounced back to nearly their original shape once the pressure from the nanoindenter was released. The next stiffest were the Ys and then the any-angle Λs. The Is and the Ωs were the weakest in the nanoindentation tests.

According to theoretical calculations, performed by team member Yang Yang in Yakobsons Lab, the differently shaped joined-up nanotubes have varying strengths because of the atomic geometry at the junctions between the tubes. “Where nanotubes join, carbon atoms that normally come together in six-member rings are often forced to change their configurations, adjusting to five- and seven-member rings (known as dislocations) to remain in the lowest-energy state,” he explains. “The number of dislocations required to make a nanotube branch is different for each angle and since the dislocations take the brunt of the force exerted by the nanoindenter, those variations determine the overall stiffness of a joined-up nanotube.”

Testing the stiffness of individual nanotube junctions

The simulations also show that the local walls of the nanotubes (which are essentially rolled-up sheets of carbon or graphene) stretch enough to distribute the strain from the indenter.

Knowing which shapes of joined-up nanotubes are stronger could be important for specific applications. “Imagine if all the joined-up nanotubes were upside-down Y shapes,” says team member Evgeni Penev. “Those such as carpet would be much harder to crush under pressure.”