Researchers at Rice University in the US have made a new hybrid microsupercapacitor from graphene and carbon nanotube carpets with electrochemical properties that could come in useful for portable electronics and renewable power applications. At 2.42 mWh/cm3 in an ionic liquid, the device also has twice the energy density per volume of conventional aluminium electrolytic capacitors.

Capacitors are devices that store electric charge. Supercapacitors, more accurately known as electric double-layer capacitors or electrochemical capacitors, can store much more charge because of the double layer formed at an electrolyte–electrode interface when voltage is applied.

As the demand for portable electronics increases, researchers are now turning their attention to microcapacitors for energy storage. Although a variety of materials, such as carbide-derived carbon, onion-like carbon and laser-reduced graphene, have been studied, none of these seems to be compatible with line-filtered alternating currents of 120 Hz.

120 Hz AC line filtering smooths the so-called leftover AC ripple on direct current voltage buses in electronic devices powered by conventional power sources. The full-wave rectified 60 Hz AC power is then filtered to produce pure DC voltage. Such filtering is especially important in renewable electrical power produced by wind or hydroelectric turbines in which frequencies can vary because of the irregularities in the flow of wind and water.

Impedance phase angle

Scientists usually characterize filtering efficiency using the “impedance phase angle” at 120 Hz. Although aluminium electrolytic capacitors (AECs) are currently used in such applications, these devices do suffer from the fact that they have relatively low energy densities. Supercapacitors could come into their own here, but there is one problem: the phase angle of commercial devices at 120 Hz is close to 0°.

A team led by James Tour and Douglas Natelson at Rice is now saying that hybrid supercapacitors made from graphene and CNT carpets show impedance angles as large as –81.5° at 120 Hz frequencies, which is comparable to the values seen in AECs. “These high angles are most certainly thanks to the seamless interface between the nanotube-graphene junctions in the device,” said team member Jian Lin.

Promising properties

The new devices also have specific capacitances of up to 2.16 mF/cm2 in aqueous electrolytes and 3.93 mF/cm2 in ionic ones – figures that compare well to those seen for commercial supercapacitors. What is more, the measured discharge rate of up to 400 V/s is hundreds of times higher than that seen in most supercapacitors and allows the devices to deliver a theoretical maximum power density of 115 W/cm3, even in aqueous electrolytes. In ionic liquids, the energy density is as high as 2.42 mWh/cm3.

"All of these characteristics mean that such hybrid devices could be ideal as discrete power sources in future electronics," Lin told nanotechweb.org.

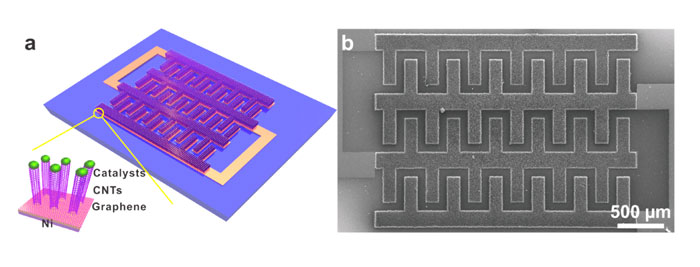

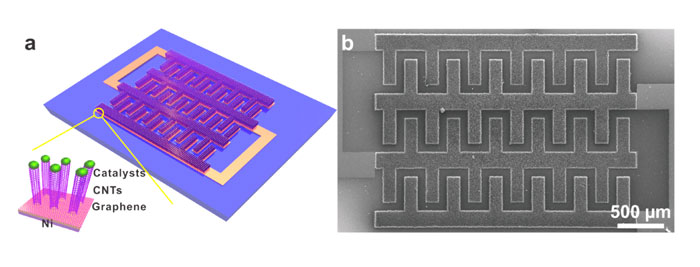

The Rice team made its microsupercapacitors using conventional photolithography on Si/SiO2 substrates, followed by deposition of a 10 nm chromium adhesion layer and a 450 nm nickel-graphene growth catalyst layer. Few-layer graphene was then grown on the patterned nickel electrodes by chemical vapour deposition (CVD) and catalyst particles of Fe/Al2O3 patterned and deposited on the few-layer graphene. In the final step, CNT carpets were synthesized on the graphene by CVD.

"Since the 3D hybrid material also has fantastic electrical conductivity and high surface area, it would now be interesting for us to look into other applications for these supercapacitors, such as advanced electrodes for lithium ion batteries," said Lin.

The current work is reported in Nano Letters.